Carbon fibre is very expensive when compared to other similarly durable materials. However, this is presently altering. Once as expensive as $15 per pound, carbon fibre is now available for as cheap as $7. That's impossible, right? The factors influencing the price of carbon fibre are rapidly improving.

Components of Final Product

A composite substance, like carbon fibre. Since carbon fiber price is just one component of a composite, the price will also depend on the other elements used to make the composite. Composite materials such as Polyacrylonitrile (PAN), Rayon, and Pitch are used to create carbon fibre.

Energy

The price of carbon fibre includes not only the material itself but also the energy required to produce it. After the resin fibres are fabricated using PAN and other precursors, they undergo a series of treatments including chemical processing, heating, and stretching. After that, carbon atoms strengthen the fibres through carbonization.

Production

Carbon fibre production requires human work and mechanical processing. To manufacture carbon fibre requires a high level of expertise. Because of this, making carbon fibre is not a job for everyone. Carbon fibre production machinery is also cutting edge. The high cost of these machines might significantly increase the final selling price.

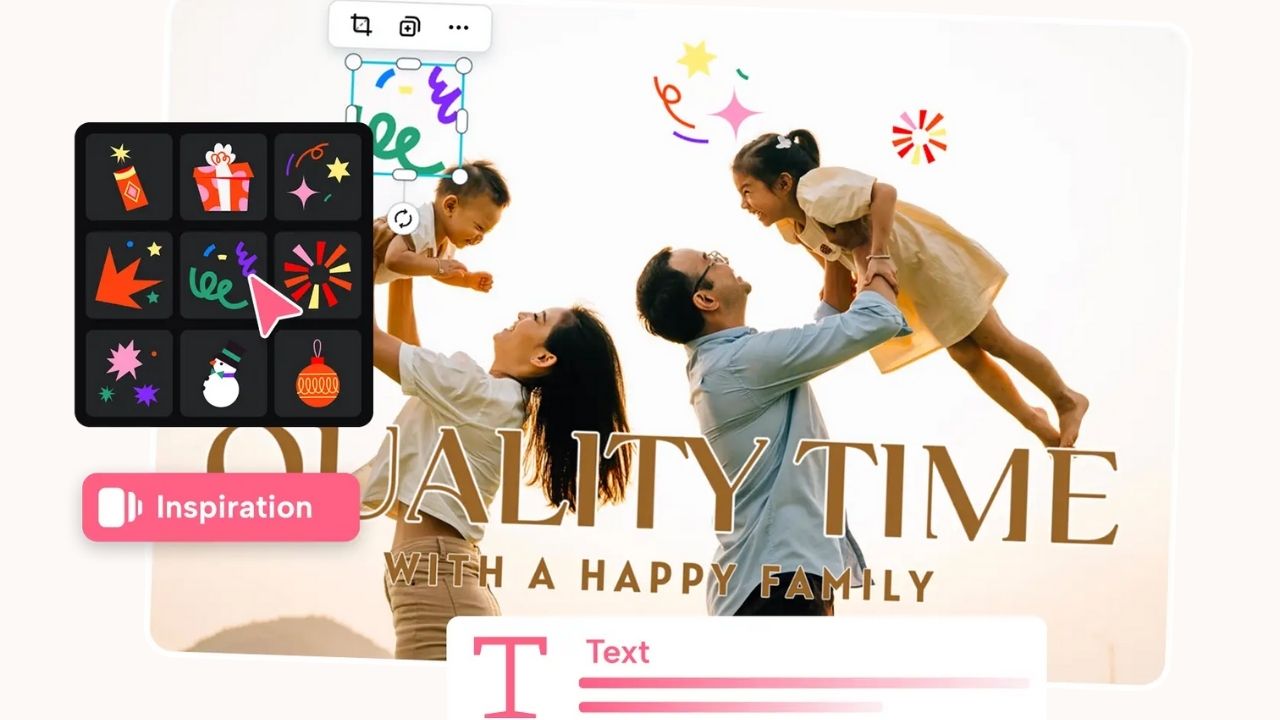

Technology and Software

The price of technology encompasses a broader range of parameters than only the price of machines used in production and assembly. In the composites industry, new software is being released. For instance:

Falling Price

The primary considerations in manufacturing are raw resources, energy, and production software and technology. However, thanks to recent technological breakthroughs, the overall cost of producing carbon fibre is decreasing.

Formulation of Precursors and Standard Operating Procedure

Polymerization, dope preparation, winding, and packaging are only some of the processes involved in making PAN precursor fibres. Industrial lines have stripping columns to recover any unreacted monomer and recycle it into the reactor.

Challenges And Method Of Spinning

The sensitive nature of the job and the inability to research the companies' technological acquisition histories made it difficult to collect the data connected to PAN precursor manufacture. Manufacturing of precursor fibres can be accomplished by a variety of spinning techniques. However, commercial producers mostly use wet and air gap spinning.

Models

When making these calculations, it is prudent to assume a precursor fibre production facility with a throughput of at least 10,000 tons per year to get a good idea of the impact of the various parameters that go into determining the cost per kilogram of PAN precursor.

Production of Carbon Fibre

Today, heat treatment occurs at multiple stages throughout the process of making carbon fibres from PAN precursor fibres. When PAN fibres are subjected to specific pressures and dwell periods, they are thermally stabilized in air heated to 225–260 °C.

For the fibres to survive the subsequent high temperatures, this step is crucial. Next, the material is carbonized at temperatures between 500 and 1500 °C in an inert environment, first using the low-temperature (LT) method and then the high-temperature (HT) method.